Matthew Cameron looks at how twist rate relates to projectile length and velocity, and how that affects our choice of bullet in the field

credit: Archant

credit: Archant

When I was considerably younger there was a dance craze called ‘doing the twist’. Personally, I was never that interested, but now that I am older, twist is of great interest to me, mainly in reference to rifle barrels. Nowadays, because of the projectile options available, it is necessary to be aware of the twist required for a particular projectile before you attempt to develop your load using any particular powder.

The basic factors are well known – in simple terms, the longer the projectile in relation to calibre, the faster the twist required to stabilize the projectile in flight. It follows that the longer projectiles are also heavier in weight for any given calibre. The greater the velocity, within limits, will also aid in keeping any given projectile stable. At the other end of the scale, a shorter projectile can accommodate a lower, slower twist rate.

Perhaps the biggest shift in recent times has been the virtual explosion, in numerical terms, of really good quality hunting projectiles. In addition to those manufactured by the major companies, smaller custom makers are producing specific projectiles for hunting, usually in a few calibres. Furthermore, the construction of many projectiles has changed. There are ‘all copper’ projectiles along with other metals; they are, of course, long for their weight, and many have a polymer tip. Does this create a twist problem for the rifleman?

The correct twist, when matched with the projectile of your choice, will provide maximum accuracy, all other items being considered. The incorrect twist will not stabilize your projectiles and accuracy will suffer. If, like myself, you are interested in long-range varminting, then matching the twist to the projectile is vital to achieving the desired result. Aside from long-range shooting, your hunting projectile should also be compatible with the barrel of your rifle.

credit: Archant

credit: Archant

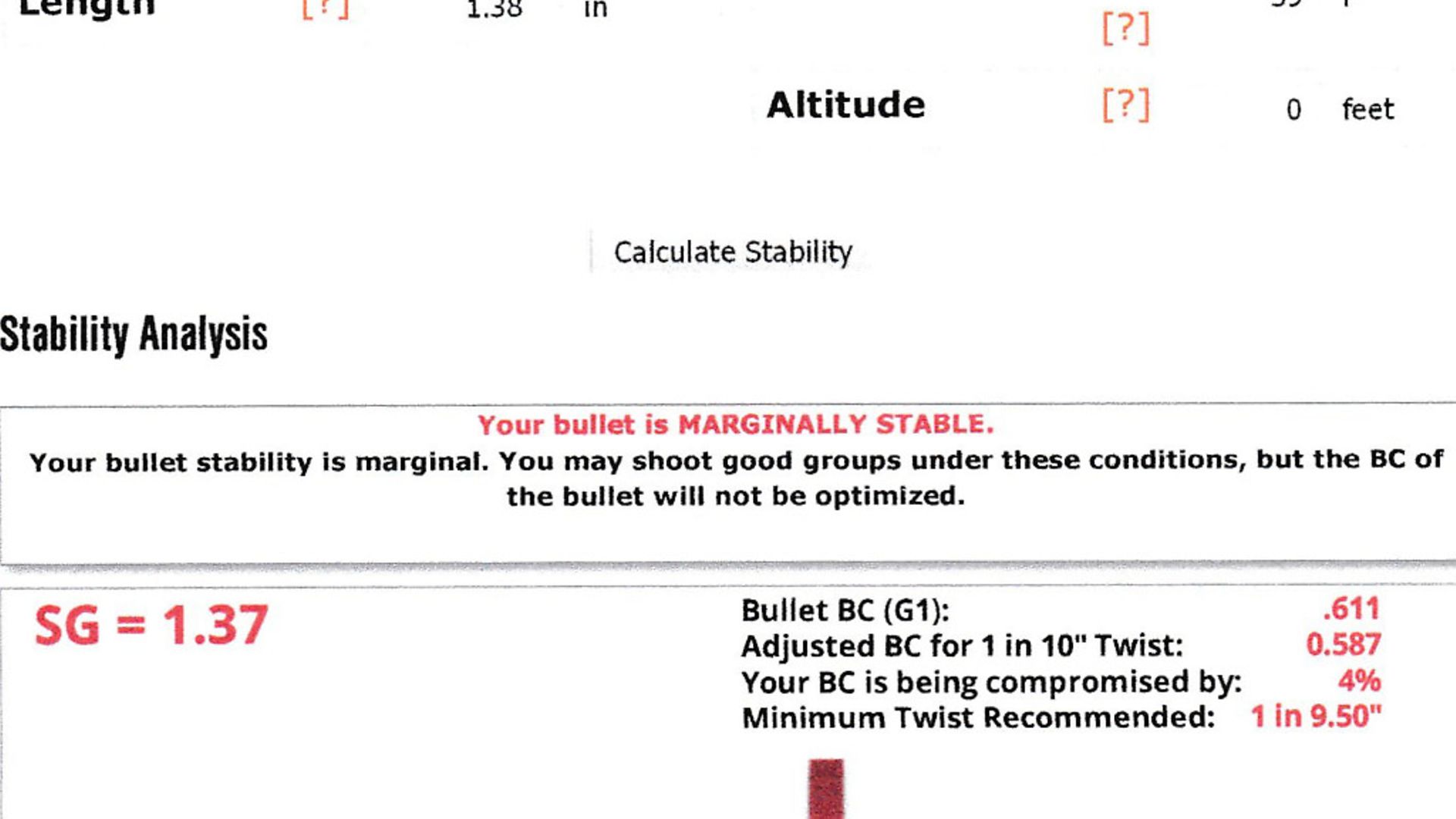

Thus, with these factors in mind, any particular projectile that is marginal in terms of twist rate may in fact become suitable if the velocity is fast enough. You can see this by using any number of computer programs and fiddling with the figures: Load from a Disc and Berger’s online Stability Calculator are two examples.

The stability factor (SG) minimum figure to ensure good accuracy is 1.5, where such a figure(s) are quoted. If not spun quickly enough, the projectile becomes unstable and thus less accurate. Note that the Berger program actually applies to boat tail projectiles. By comparison, Load from a Disc will accommodate both flat base and boat tail types. For two projectiles of the same weight, a boat tail model will require an extra inch of twist to ensure stability when compared with its flat-based cousin.

While longer, heavier projectiles require faster twist barrels for stability, what happens when you fire lighter, shorter projectiles in the same barrel? The short answer is: probably nothing. But there may be some adverse effects depending on the barrel and a particular projectile. If the projectile is a frangible varmint type that is designed to blow up easily on small, light-boned animals, excessive twist may tear the projectile apart shortly after exiting the barrel. In addition, there may be more barrel wear due to the excessive rotation. We come up with that term ‘balance’ again. However, the short answer is that while you can shoot light, short projectiles in a fast-twist barrel the reverse is not correct. It is noticeable that some rifle barrels will shoot a particular projectile with better accuracy than others; sometimes even small differences actually do make one projectile a veritable tack driver when compared to another.

There have been some notable failures in firearms history whereby the manufacturer designed a rifle with an incorrect barrel twist. The .243 Winchester V 6mm Remington is a classic example and most firearm writers have covered the subject at some time or another. I do not intend to add to the discussion. If you are interested, there is plenty about it on the internet. In similar fashion, the .260 Remington was released with a 1:10 twist barrel, too slow to stabilize the long 6.5mm projectiles.

Much the same applied to the .223 Remington, barrel twists were changed with different ammunition, i.e. different projectiles were unstable even with quite modest changes in projectile length and weight. The final bit of theory is that hotter ambient temperatures can reduce the required twist rate because the projectile speed is higher, and the same applies to increasing hunting altitude.

credit: Archant

credit: Archant

Applying the theory

While all of the above is very nice to know, what really counts is how we apply this theory in the real world of rifles and ammunition. Perhaps the centrefire rifles in .224 calibre are a starting point.

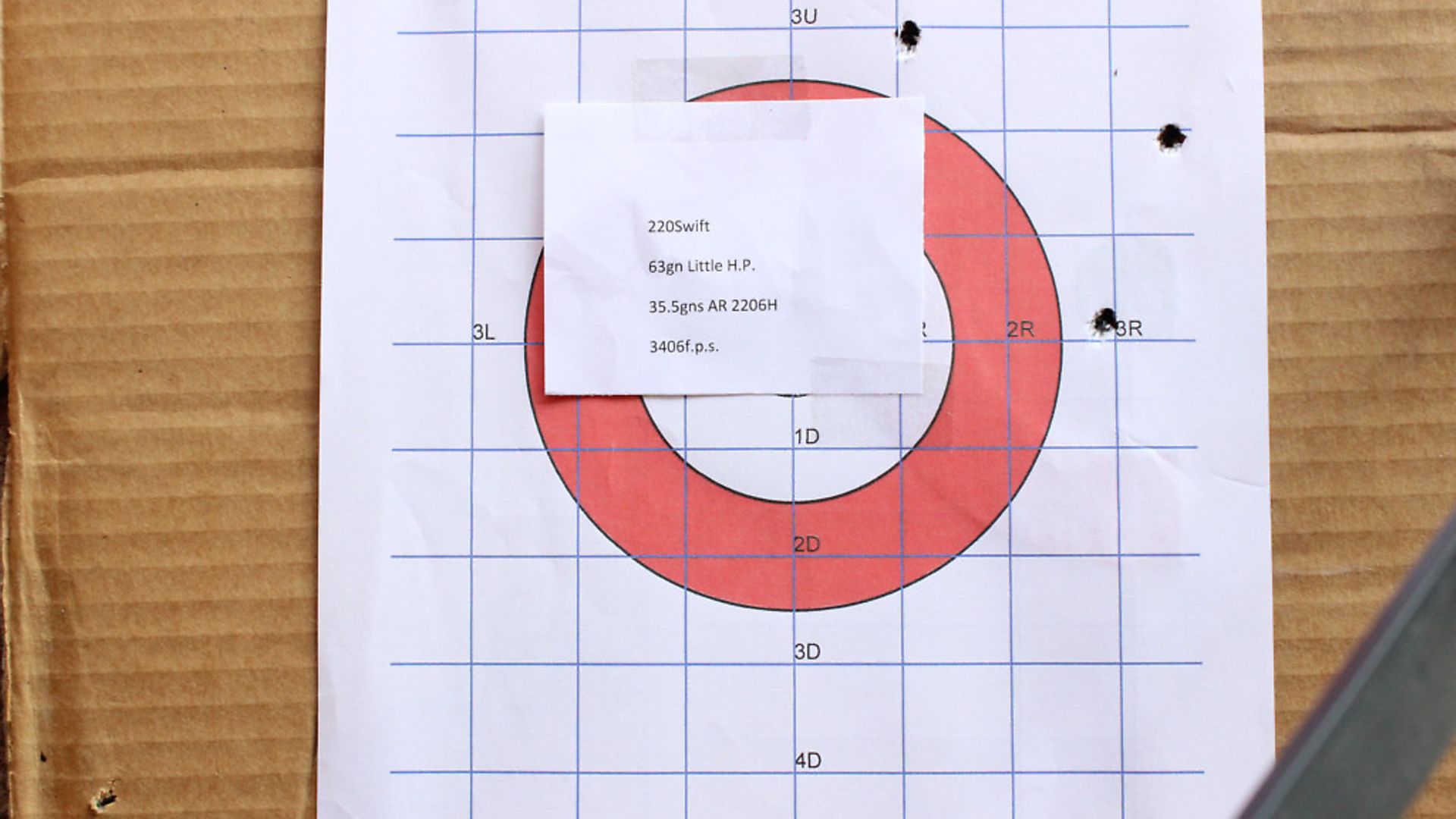

The family .220 Swift, circa 1990, has a 1:14 barrel. To my knowledge, this barrel twist rate was set at the inception of the cartridge in 1935, and did not change. After this date, projectiles above 55gr in weight became available, however by then the cartridge was no longer highly thought of by the fickle shooting public. Certainly, those who had custom barrels chambered for much faster twist did shoot bigger projectiles with accuracy.

With the family Remington chambered in .220 Swift, a standard load is a 55gr JLK hollow point at 3,544 fps, grouping consistently at a bit less than an inch. According to Load from a Disc, this projectile needs a 1:15 twist to be stable; however, this particular projectile is stable enough in the 1:14 barrel.

credit: Archant

credit: Archant

The rifle also shoots 50gr Nosler solid-base projectiles at some 3,834 fps and is very accurate at this speed – groups are consistently less than 0.75” in size. Load from a Disc suggests that the barrel for this projectile should be 1:14 – perhaps a perfect fit? It’s certainly the most accurate Swift load. Coincidence? Perhaps not. But the barrel will not stabilize 63gr projectiles, as these particular types require a 1:12 twist.

It is also interesting that the Hornady reloading manual No.9 and the Barnes Manual No.4 contain notes on various cartridges indicating that certain projectiles within that calibre will not stabilize in particular barrels. This is very useful information: many of these notes apply to projectiles that are not excessively long.

Of course, the question is: just when does a particular projectile become unstable? If the two criteria that control stability are velocity and projectile length, we can only control velocity and eventually, when we reach the maximum load, there is nowhere else to go!

In addition, it is highly probable that in any cartridge, once we have reached this upper limit and the achieved accuracy is not within our parameters, we either have to reduce the projectile length and weight, or perhaps try a different powder with the hope that it may provide better velocity and overcome a potential accuracy problem.

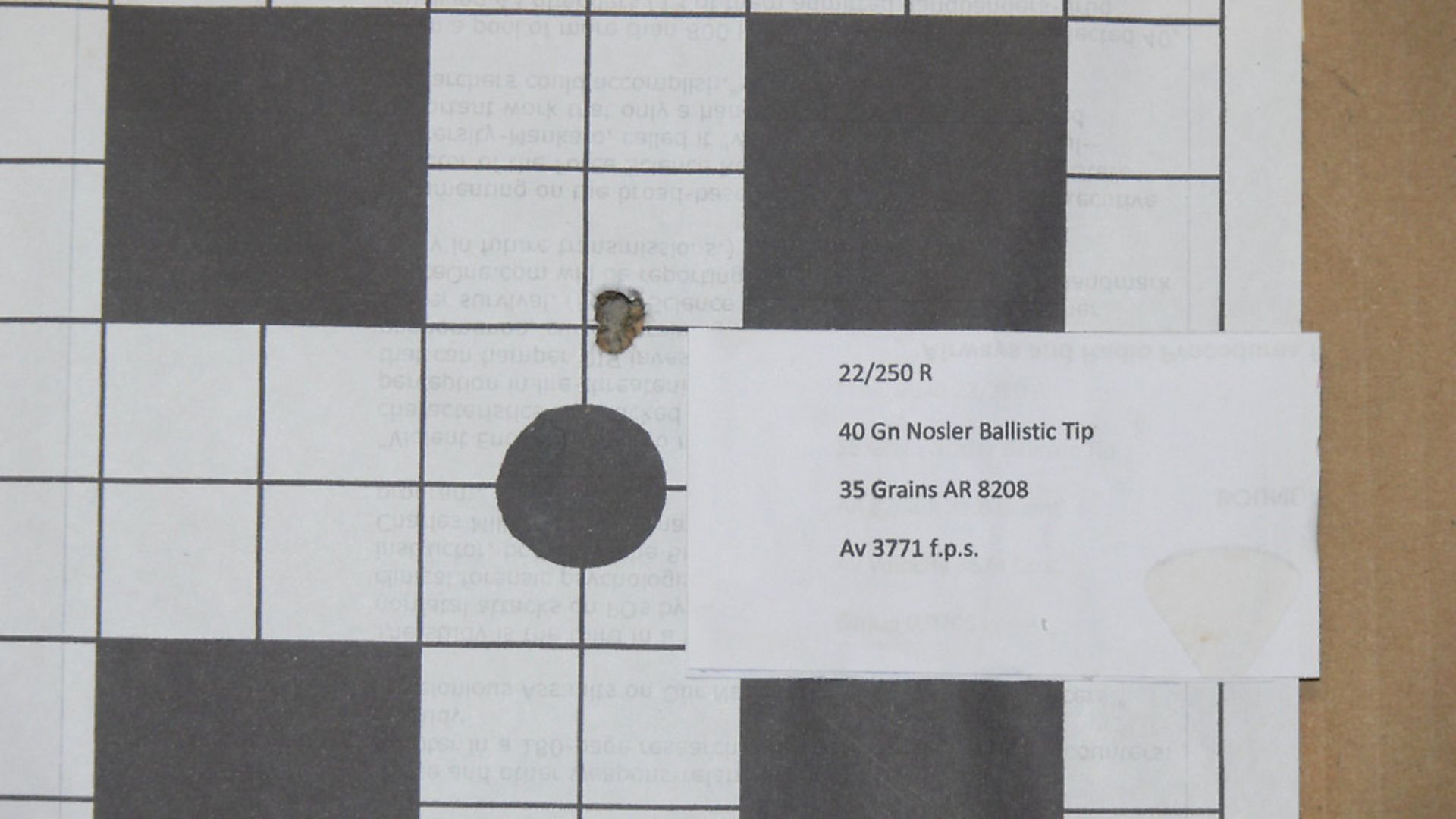

The more modern Savage LRPV in .22-250 Remington calibre in the family gun safe is only around nine years old at the time of writing. In my opinion, Savage was very smart with this rifle, offering a barrel in either 1:12 or 1:9 twist, and I chose the faster twist as I wanted to shoot longer range, heavier, varmint-type projectiles. It certainly added flexibility to the projectile choice. The result was that this rifle shoots projectiles from 40gr to 65gr in weight, with the best loads for nine different projectiles averaging 0.54”; it is very consistent and predictable. It is a pity that more rifle manufacturers do not offer the option of a different twist barrel.

credit: Archant

credit: Archant

From a theory point of view, we looked at the Sierra range of projectiles in heavier weights and typical velocities to compare with the above. The 69gr hollow point boat tail has a length of 0.895” and, according to the Sierra manual, should attain a nominal velocity of 3,150 fps. If we feed these figures into the twist calculator in Load from a Disc, it suggests that a rate of 1:10 would be required. Even if we were able to increase the velocity to 3,250 fps it would still require a 1:10 twist rate. In similar fashion, the 80gr hollow point boat tail projectile, which is 1.080” long at a nominal 3,000 fps, requires a twist rate of 1:7. If you can increase the velocity to 3,100 fps, the rate drops to 1:8.

When we start considering the light hunting calibres, the waters seem to get a little muddier! In .243 Winchester calibre, most rifles are fitted with 1:10 twist barrels, with eight exceptions in 9”, 91/8” and 9¼”. Until recently, the upper end of the projectile weight range in .243 calibre projectiles was 105gr.

Now, several manufacturers are producing both target and hunting projectiles in weights of 107gr and 115gr. Note that normal factory rifle twists will not stabilize these weights. The two pages in my Berger manual specifically require a twist rate of 1:8 or faster. Of personal interest is a new 1:7 barrel for my Switch Gun in .243 Ackley Improved, the twist rate of 1:7 being specifically for low-drag projectiles of 105gr and above.

credit: Archant

credit: Archant

Some of the older cartridges are limited in twist rates. As an example, only 11 manufacturers for the .25-06 Remington are mentioned, and all use 1:10 twist rates. Further, the .257 calibre projectiles are about the upper limit for heavier projectiles in relation to calibre. My bullet database fails to mention any projectiles above 120gr in weight for this cartridge.

When we look at the 6.5x55mm calibre, the most common twist rate is 1:8”. This is not surprising considering the long, relatively heavy projectiles in this calibre.

The Tikka T3 family has a twist rate of 1:8 and provides a good example of a barrel shooting two different projectile weights. Both are flat-base custom protector points – the 140gr is 1.18” long with a nominal BC of .444, and is normally propelled at an average speed of 2,450 fps. If we feed these figures into Load from a Disc, it indicates that a twist rate of 1:9 is required for stability. In similar fashion, the 160gr projectile is 1.34” long at a nominal velocity of 2,363 fps with a BC of about .509 and requires a twist rate of 1:8 to be stable. Thus the barrel is able to handle both projectiles without any problems; both have had excellent accuracy right from initial load development and both consistently group around 0.80” for three shots from a fouled barrel.

credit: Archant

credit: Archant

When we get into the heavier hunting cartridges, it is no surprise that the factory twist rates are closely allied with the range of projectile weights available. I would suggest that heavy-for-calibre custom projectiles may cause problems. One such cartridge that I am currently involved in is the 7mm Remington Magnum. The majority of current rifles have a twist rate of 1:10 with two at 9½” and a heap more at 1:9¼. There is an interesting dilemma of attempting to shoot custom 162gr low-drag and protector points out of a 1:10 barrel. Both computer programs, Load from a Disc and the Berger Stability Calculator, show the projectile to be just viable in terms of stability. Propelled with a hefty load of local AR 2225 powder (= RE-25) the load is sub-MOA with a velocity average of 2,870 fps.

The other issue we have not touched upon until now is factory ammunition. For the non-reloader, the range of projectiles used by the various factory offerings has expanded. It might pay to check that the projectile used is compatible with your barrel twist.

Perhaps the main lesson over many years is that theory is sometimes necessary as a background, but nothing beats running the projectile over a chronograph and onto a target to assess just what a particular cartridge/rifle combination is capable of in terms of velocity and, more importantly, accuracy.

credit: Archant

credit: Archant

credit: Archant

credit: Archant