Chris Parkin explores a new powder and bullet combo - IMR Enduron Powder & Hornady 143 ELD-X Bullets in 6.5 Creedmoor... find out how he got on here!

![[Ignore this one Trev]](/resource/image/8103676/landscape_ratio16x9/1920/1080/9698203a1f6ef685efca352e95c6735c/Lz/imr-enduron-3-f1df22b6.jpg) credit: Archant

credit: Archant

IMR Enduron Powder & Hornady 143 ELD-X Bullets in 6.5 Creedmoor - BRIEF OVERVIEW

PROS: The closest performance yet for me to H4350; Reliable metering and consistent; Clean burning with minimal barrel residues even from sub pressure starting loads; 143 ELD-X are already well proven for ballistics and performance on medium game

CONS: Performance has to balance relative greater cost

VERDICT: I have relied on H4350 for a decade, IMR 4451 Enduron is the closest yet but longer-term use is needed through the seasons and batches to confirm its performance in relation to the powder it seeks to replace.

RRPs

£59.00: IMR 4459 Enduron reloading Powder

£51.30: 143gr 6.5mm Hornady ELD-X Bullets

CONTACT: Edgar Brothers 01625 613177

credit: Archant

credit: Archant

IMR Enduron Powder & Hornady 143 ELD-X Bullets in 6.5 Creedmoor - IN DEPTH TEST & REVIEW

The loss of Hornady’s Extreme powders from UK shelves a couple of years ago hit quite a lot of reloaders hard. Two specific Extreme Powders, Varget and H4350, were almost pivotal in terms of ballistics for cartridges like .223 and .308 in the former and .243 and .260/Creedmoor and 30-06 in the latter.

IMR’s new Enduron range seeks to offer reliable alternatives to these, with anti-copper fouling formulations and chemical engineering in line with current environmental concerns, as well as temperature stability.

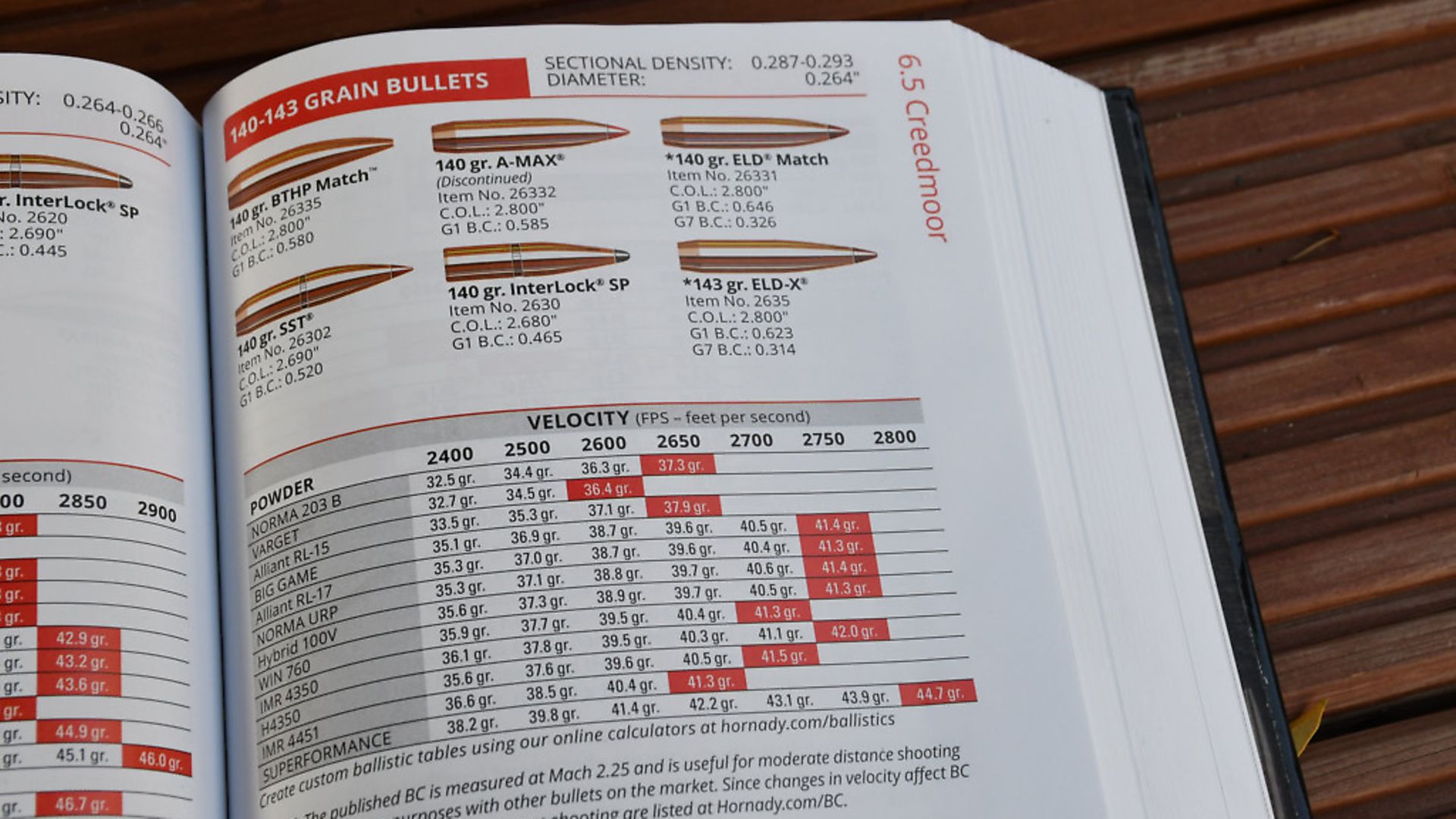

It’s impossible to cover the full test regime of one powder in a single rifle, especially when they are likely to be used in a broad spread of cartridges, but I was keen to see how Enduron 4451 worked in one of H4350’s classic roles – the popular 6.5 Creedmoor – using exact factory recommended loads.

I had to wait for a reliable and proven Creedmoor rifle for this review, so when the Sauer 100 Fieldshoot proved itself worthy, I began preparing some of its once-fired brass, as would many reloaders seeking to reproduce factory performance.

credit: Archant

credit: Archant

Reloading reliability

This was never intended to be a full tailoring exercise; the goal was reliable reloads following the strict instructions from Hornady’s 10th Edition reloading manual. I will add that if you want to start reloading, recipes are not the key; read the manual that shows you how and why reloaders need to do what they do and learn to analyse the results of what is ejected from the muzzle, on paper and over the chronograph, as well as important inspection of spent brass.

I was perhaps guilty myself of suggesting running before walking last month in my N555 article, interchanging 6.5 Creedmoor/.260 Rem data without clearly stating the differences, but the Creedmoor data is a workable starting load for the less common .260 with slightly larger cartridge volume.

IMR 4451 is a medium-sized kernel, 1mm in diameter and 1.79mm long on average, and works quite well through volumetric measurement alone with smooth flow and no bridging in the funnel from powder measure/drop tube to the scale pan. Specific “Volume Measure Density” is 0.0713 (4.0cc/sample weight in grains=VMD). This is not a unit we seem to consider much in the UK, but US reloaders like to know this unit for faster calibration of volumetric powder-measuring systems – definitely a priority when using multiple turret progressive presses to create large volumes of ammo.

Its specification indicates IMR’s commitment to the long-term volumetric stability of a powder expected to see long-term use, especially in the Precision Rifle market; along with IMR4166 (seeking to replicate Varget), this is a precious goal, as in past years H4350 and Varget have shown to draw and hold a significant number of the valuable US PRS market.

Although IMR previously made a ‘4350’ powder to closely replicate Hodgdon H4350, it couldn’t promise the ‘Extreme’ temperature stability that’s key to success in a continent with potentially major temperature shifts between venues.

I was initially able to get loads down to 0.2gr consistently from a volumetric measure. I always trickle final results to within 0.1gr and I prepared five each of 36.6, 38.5, 40.4 and 41.3gr, exactly as specified in the Hornady manual (as I did 15 years ago when I first started reloading!).

credit: Archant

credit: Archant

Back to basics

I wanted to remind myself of the initial stages of reloading, which I now take for granted, because I take a more liberal approach on occasion. A reloading manual explains the process, and it’s especially important to inspect pre-loaded cases and those fired with your new recipes to record results and learn trends for your own rifle.

Having visited the Hornady factory and test range where the book was written, I know that the reloading data is researched and recorded using a single test barrel. The visit was memorable, almost like a pilgrimage to a book I considered as gospel and to which I still regularly refer.

Checking each case for powder residue, primer condition, case head condition etc. when loaded at the recommended Cartridge Overall Length (COL) of 2.800” ensures magazine/chamber compatibility within SAAMI specification to any rifle. This is just as important as looking at the velocities and the groups shot on target.

The reloading manual will state the barrel length and twist rate of the test gun used, as well as primers and case brand. I used CCI Large Rifle Primers in full-length factory resized cases from the Sauer. This rifle has a similar, 24”/610mm, 1-8” twist barrel to that of Hornady’s test gun, so as charge weight increased, I was pleased to see my chronograph reporting figures within 30fps of the manual’s predictions. However, this is not super critical; most barrels and rifles will produce slightly differing results and it’s unusual for any rifle to replicate factory data exactly.

All barrels seem unique in temperament, so I look for the trends, not the exact velocity results. I finished my ladder test with 2677fps average speed (Predicted results were 2650fps on average), showing on the chronograph with a 16.6mm 5-round group average at 100 metres.

This exceeds the MOA standard and although not competition level, is a clear demonstration of how simplicity is key to reloading – following instructions and learning to walk before running. Once this stage is complete, reloading can become a goal in itself with experimentation with seating depth generally following that of charge weight, but only if safe and desired.

Every element of the procedure can be tweaked but don’t feel you have to, because after 15 years of reloading, I have come to accept that primary results usually indicate a bullet/barrel/powder combination that is likely worth further experimentation. Some barrels and some bullets will just never be friends and I don’t try to make them, because the margin of failure is always too close.

credit: Archant

credit: Archant

Thanks To

Forster Reloading Dies and Coaxial Press

www.hannamsreloading.com

01977 681639

credit: Archant

credit: Archant

credit: Archant

credit: Archant